The hot forging process is probably one of the most known in the market, considering that it has been around for centuries. But how much do you know about this forming process? Well, the hot forging process is one of the has been widely used and continues to dominate the metal forming industry.

For the newbies, there are many facts about this forming process that they should know. Here are just some of the few key facts worth noting:

Hot Forging Melts The Billets

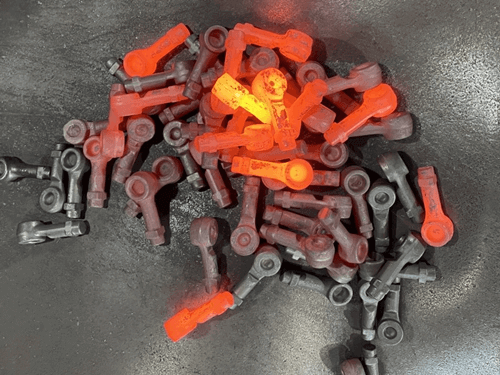

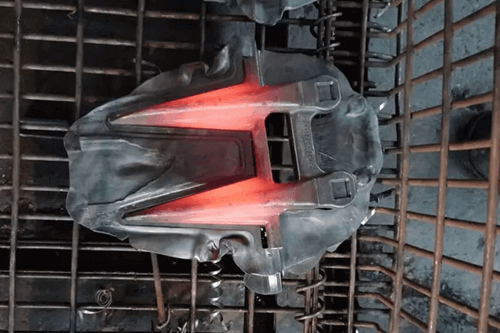

The hot forging process makes use of hot temperatures to soften the metal being forged. This is why it is called hot forging. The metal being deformed is heated to the crystallization level, where it has also reached the plasticity level.

While metal has melted, it is pressed or punched to form the desired shape. Therefore, a lot of heating is needed for the hot forging process to be a success.

It Uses Hydraulic Equipment

After the billet has been heated to its crystallization level, it needs to be pressed for the forging to happen. This is where hydraulic equipment is needed for the punching work. Therefore, modern hot forging process setups have hydraulic machines in the assembly.

The size of the hydraulic machine depends on the amount of pressing or forging force needed. The bigger the part being forged, the bigger the force needed and the bigger the hydraulic setup.

Hot Forging Requires Heat Treatment

The parts made using the hot forging process require a lot of heat treatment. Because of the massive heating that takes place during the forming process, the cooling of the forgings is highly regulated to avoid deformities.

Therefore, heat treatment is a key stage in the hot forging process. It is a stage that greatly controls the quality of the forgings.

Produces Harder Parts

One of the reasons why the hot forging process is popular in the manufacturing industry is because of the harder forging it produces. It is a process that produces some of the best quality machine parts. This is because of the hardness and heat resistance features it offers.

Check out Hot Forging China for all your hot forgings needs.