Maybe you have been wondering about extrusion forging differences that exist in order to consider the process that suits your needs. It is important to note that there are major differences between extrusion and forging.

In both cases, however, there is the processing of a metal billet with the intention of achieving a specific shape or size. If you are wondering what the extrusion forging differences are, then here are some descriptions for you:

Extrusion

In extrusion, there is the use of strong pressure that is intended to force or drive a metal billet through a die. In this case, the die is smaller or differently shaped. The idea of driving the metal billet through the die is to ensure that the desired shape is achieved. Note that the die is shaped in a manner that matches the desired shape, hence when the metal is pressured through it, the final result will be a shape that resonates with the design of the die.

It is important to note that a wide variety of cross-sections can be produced through the extrusion process. It is for the client or the manufacturer to determine the shape he/she would want to achieve in the end.

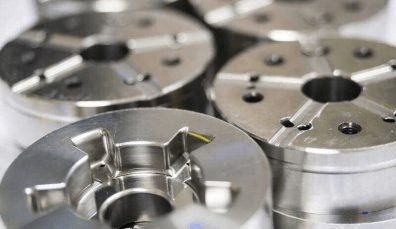

Forging

The process of forging entails hitting a metal billet using strong force or pressure with the intention of producing strong parts. The idea here is to place the metal billet on a stationary surface and then exert a strong force on it. It is important to note that the metal billet is hit with the final shape in mind.

This is why forged products are mostly found in places of stress and shock, due to the vigorous and thorough process that is involved in making such. The forging process comes in two different forms- open die forging and closed die forging. Open die forging is not necessarily aimed at providing unique specs like in the case of closed die forging.

So unlike another forging, extrusion forging is where a metal billet is forced or driven through a die.