In many industries, the success of a project is largely dependent on the quality of the forged components used. It’s thus imperative to select the right forging factory. This article seeks to inform and educate on some of the common mistakes, in the hope that you can avoid them and ensure that your projects are built on a foundation of high-quality forged components.

-

Not Understanding the Different Forging Processes

There are multiple forging processes, including open-die forging, closed-die forging, and ring rolling, among others. Each process has its own set of advantages, suited for specific applications and materials.

Mistake: Many buyers, especially those new to the industry, often assume that one forging process is as good as another. It’s vital to research and understand the nuances of each process.

-

Overlooking Quality Assurance Measures

A forging factory’s quality control protocols can make a vast difference in the final product’s consistency and reliability.

Mistake: Buyers often get swayed by cost-saving promises and neglect to delve deep into the factory’s quality assurance measures. Prioritize factories that have a robust quality control system in place, preferably backed by recognized certifications.

-

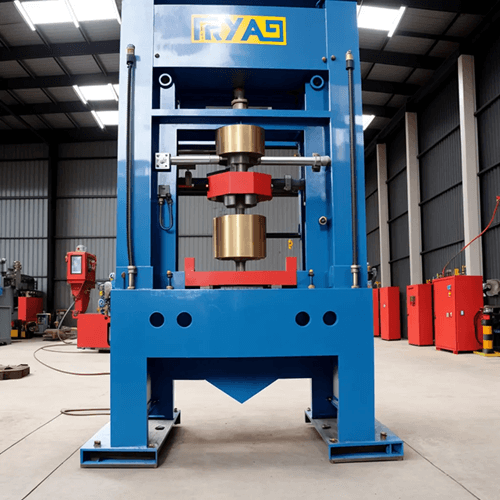

Not Visiting the Factory in Person

In the digital age, it’s tempting to finalize deals and partnerships online. But when it comes to forging, seeing is believing.

Mistake: Relying solely on digital communications and not visiting the factory. Make an effort to visit the factory in person.

-

Neglecting to Check the Factory’s Track Record

The history of a forging factory can provide valuable insights into its capabilities, reliability, and reputation.

Mistake: Not conducting thorough research into the factory’s past projects, client testimonials, and any potential red flags. Before finalizing a partnership, conduct an exhaustive background check to avoid potential future headaches.

-

Focusing Solely on Price

Choosing a forging factory solely based on the cheapest quote. Consider the overall value, including the quality of the forged products, delivery timelines, post-sales support, and more. Sometimes, paying a bit extra upfront can save you from larger costs down the line due to defects or delays.

Visit a forging factory that have an impeccable reputation for providing the market with some of the best quality and affordable forgings.