There are so many aluminum products in the market of the late, the number for forged parts have been growing fast. So what do you know about the aluminum forging process? Well, here are 5 things that you need to know:

Combining Simplicity and Sophistication

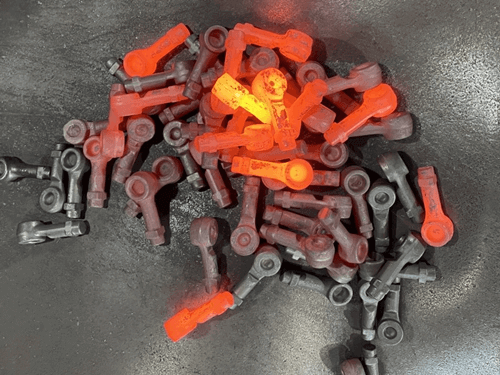

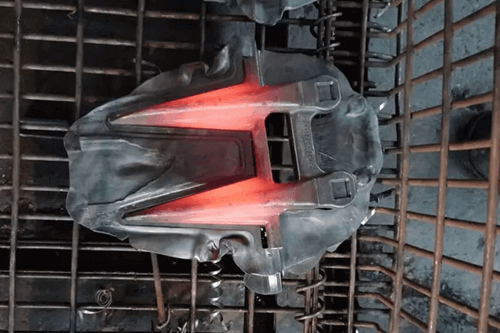

Despite its seeming simplicity, the aluminum forging process is a sophisticated operation that relies on a deep understanding of materials science, mechanics, and industrial engineering. It begins with a solid piece of aluminum, known as a ‘billet.’ The billet is heated until it becomes malleable but not molten. This temperature is carefully regulated as it significantly impacts the forging’s final quality. It is then pressed or hammered under high pressure into a die to assume the shape of the desired product.

The Material of Choice for Diverse Applications

Aluminum is one of the most commonly forged materials due to its unique combination of advantageous properties. This lightweight metal possesses excellent strength-to-weight ratio, superior corrosion resistance, good thermal and electrical conductivity, and remarkable formability. These properties make aluminum forgings ideal for a wide range of industries, including aerospace, automotive, construction, and electronics.

Different Forging Methods for Varied Requirements

There are primarily three methods used in the aluminum forging process: open-die forging, closed-die forging, and ring rolling. Open-die forging is a method used to produce simple shapes like discs, shafts, and cylinders. Closed-die forging, also known as impression-die forging, creates more complex shapes with higher precision. Ring rolling is a specialized type of forging process used to create seamless rings with controlled wall thickness.

Aluminum Alloy – Expanding the Scope of Possibilities

Aluminum can be combined with various other metals to form alloys, significantly expanding the range of applications for the forging process. These aluminum alloys offer different sets of characteristics to meet specific industry needs. For example, alloys with copper (2000 series) and zinc (7000 series) provide high strength, while alloys with manganese (3000 series) offer excellent workability.

Quality Assurance is Crucial

Quality assurance in aluminum forging is a multi-tiered process. From the selection of raw material to the final product, every step is carefully monitored to ensure that the forged parts meet or exceed the required specifications. Techniques such as non-destructive testing, including ultrasonic and radiographic testing, are often employed to inspect the integrity of the finished product.

Read more about the aluminum forging process and the aluminum forgings.