Steel is one of the metals that have been widely in the manufacturing industry. Being one of the hardest metals means that it is widely used for making various machine parts. But steel comes in many versions depending on the alloys used. One of the commonly used alloys is the 4130 steel grade.

We are going to at some of the things one needs to know about hot forging 4130 grade. It is one of the metals that’s widely used because of the good properties it offers. Here are some of the crucial things you need to know:

4130 Properties

One of the things you need to know about hot forging 4130 is its main properties. The 4130 is a grade low-alloy steel that contains molybdenum and chromium as the hardening and strengthening agents. It is one of the most versatile steel alloys because of its good corrosion resistance and strength. It also offers a good combination of strength, toughness, and fatigue strength. So, it is one of the metals used to make products that need strength and hardness features.

Hot Forging 4130 Temperatures

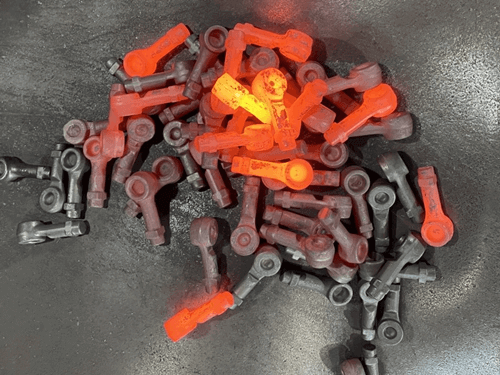

Because this steel material is made from two different alloying materials, the forging temperature can be a big issue. That’s why it is recommended that you get the right hot forging 4130 temperatures, considering the three metals forming it. Experts recommend between 2250 and 1750 º F (1230 and 950 º C) temperature for the steel grade. But to get the best grain size, you need to lower the finishing temperature. This is a very important factor to consider.

Heat Treatment

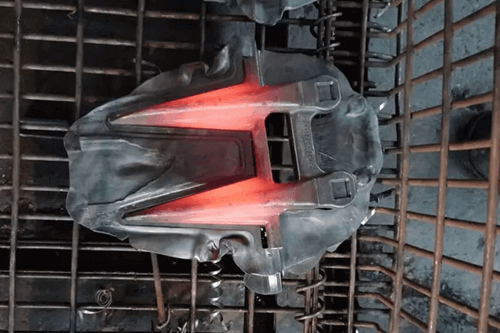

Hot forging 4130 must also include the heat treatment process. This is an essential aspect of the entire forging process. Like most of the hard metals that are hot forged, it is easy to lose the fine grains of the forged object is left to just cool immediately after forging. That’s why heat treatment is highly recommended to ensure that the product’s mechanical properties have been maintained. There are many heat treatment process that you can use depending on what you are forging.

Hardening

Though 4130 grade is one of the hard steels, it also requires some form of extra hardening after forging. The heat treatment is one of the hardening techniques that comes out automatically. But there are other hardening processes that are used, like soaking and cooling.

Steel is one of the metals that have been widely in the manufacturing industry. Being one of the hardest metals means that it is widely used for making various machine parts. But steel comes in many versions depending on the alloys used. One of the commonly used alloys is the 4130 steel grade.

We are going to at some of the things one needs to know about hot forging 4130 grade. It is one of the metals that’s widely used because of the good properties it offers. Here are some of the crucial things you need to know:

4130 Properties

One of the things you need to know about hot forging 4130 is its main properties. The 4130 is a grade low-alloy steel that contains molybdenum and chromium as the hardening and strengthening agents. It is one of the most versatile steel alloys because of its good corrosion resistance and strength. It also offers a good combination of strength, toughness, and fatigue strength. So, it is one of the metals used to make products that need strength and hardness features.

Hot Forging 4130 Temperatures

Because this steel material is made from two different alloying materials, the forging temperature can be a big issue. That’s why it is recommended that you get the right hot forging 4130 temperatures, considering the three metals forming it. Experts recommend between 2250 and 1750 º F (1230 and 950 º C) temperature for the steel grade. But to get the best grain size, you need to lower the finishing temperature. This is a very important factor to consider.

Heat Treatment

Hot forging 4130 must also include the heat treatment process. This is an essential aspect of the entire forging process. Like most of the hard metals that are hot forged, it is easy to lose the fine grains of the forged object is left to just cool immediately after forging. That’s why heat treatment is highly recommended to ensure that the product’s mechanical properties have been maintained. There are many heat treatment process that you can use depending on what you are forging.

Hardening

Though 4130 grade is one of the hard steels, it also requires some form of extra hardening after forging. The heat treatment is one of the hardening techniques that comes out automatically. But there are other hardening processes that are used, like soaking and cooling.